“Sensor IQ is a powerful, real-time monitoring solution for power companies that detects and addresses equipment issues proactively, preventing downtime and maximizing revenue through optimal equipment performance.”

The Challenge

Power companies face a number of challenges when trying to maintain their equipment.

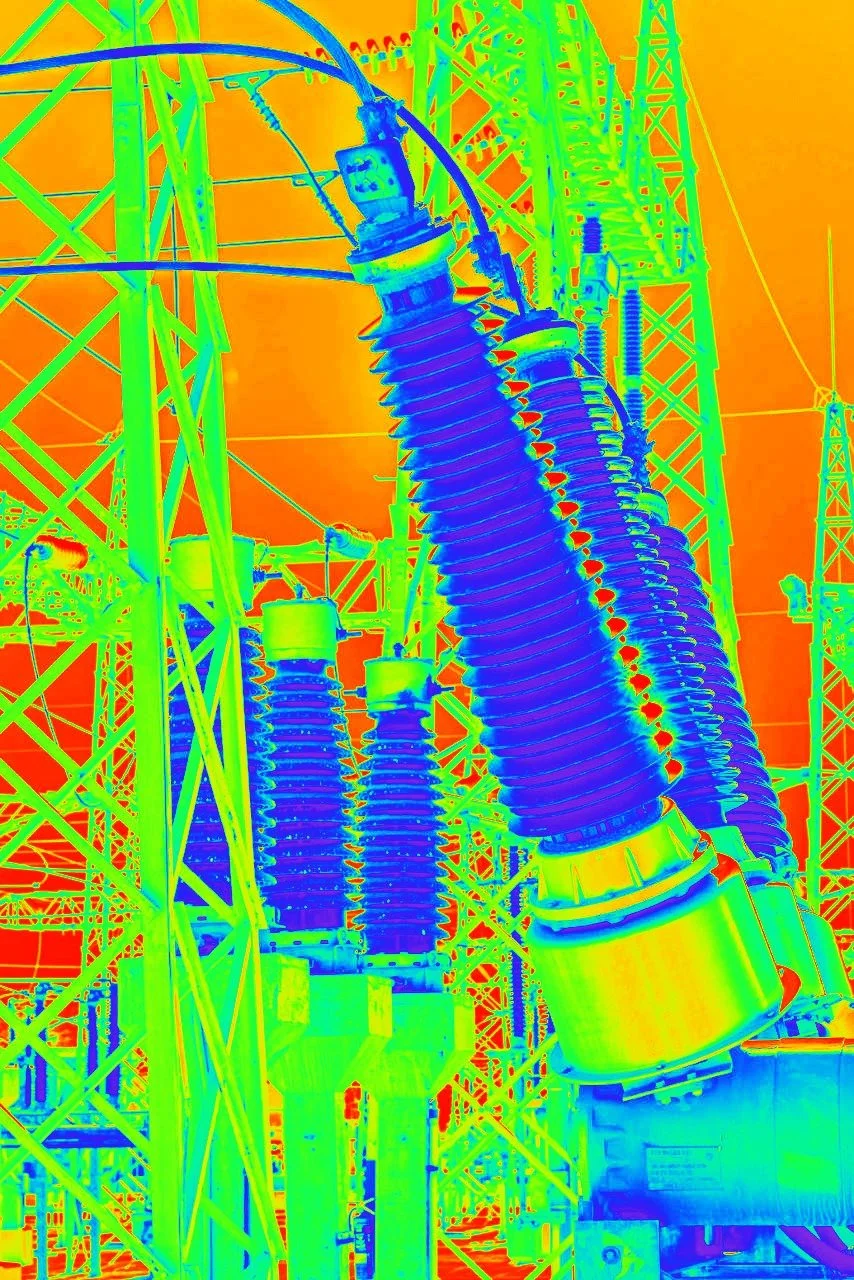

One way that power companies can monitor the performance of their equipment is by checking the temperature of various components. High temperatures can be an indicator of problems such as overheating, which can lead to equipment failures and downtime.

However, manually checking temperatures only a few times a year may not be sufficient to detect issues in a timely manner, as temperatures may fluctuate, and high temperatures may go undetected. This can lead to catastrophic failures and significant downtime, which can be costly and disrupt service to customers.

Why Sensor IQ?

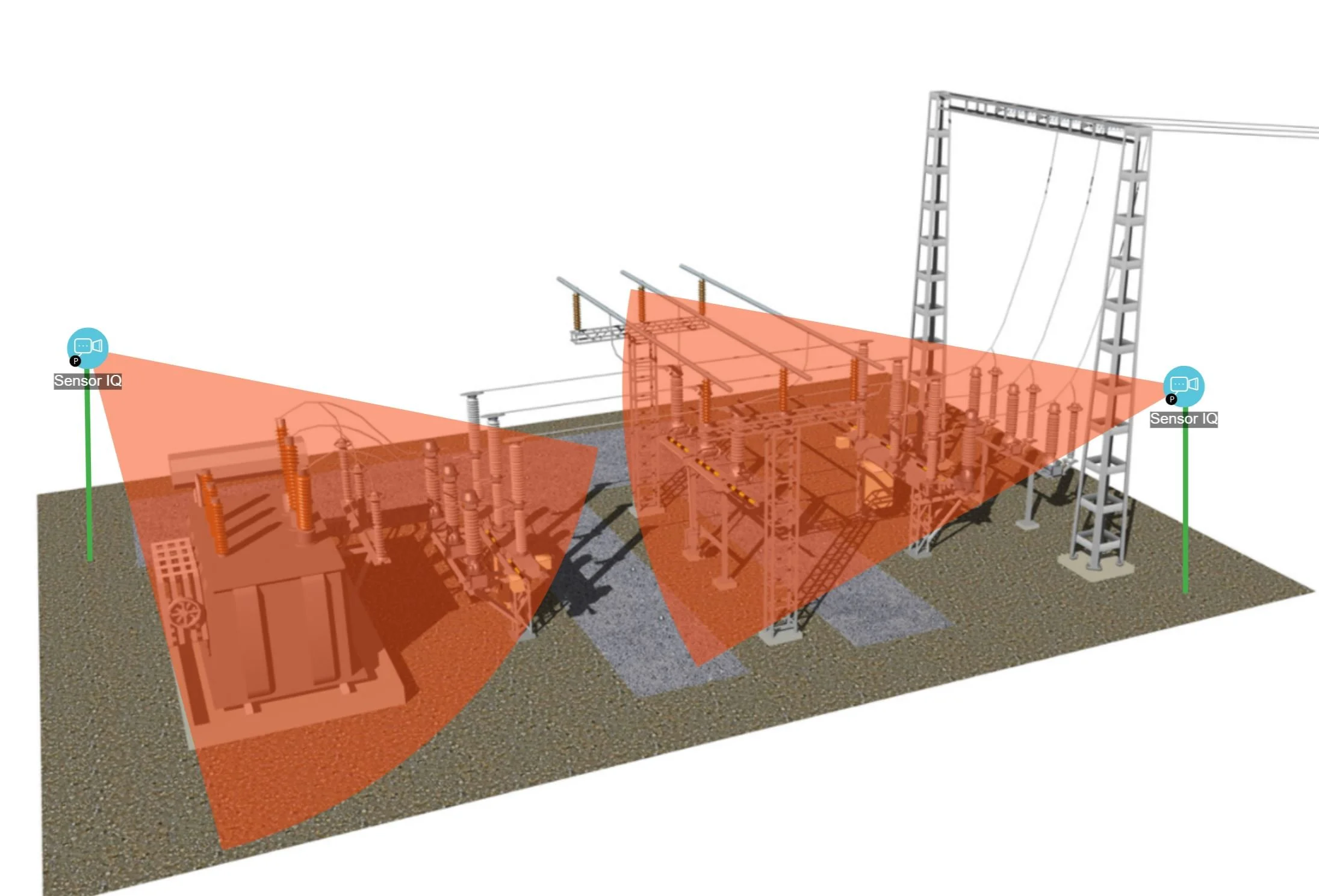

Introducing Sensor IQ - the ultimate solution for advanced real-time monitoring, detection, and notification, specifically designed for power companies

Continuous monitoring detects abnormal equipment anomalies that may indicate impending failure allowing for proactive measures to prevent equipment downtime.

multiple sensor data monitoring including, SCADA loads, ambient temp, and humidity levels in addition to only surface temperature.

Automated notifications to selected personnel via, email, SMS, mobile, and desktop applications.

Establishes baselines and trends in equipment behavior, preventing unexpected downtime with predictive analytics and reporting.

Automated monitoring reduces human error, improves accuracy and consistency of data.

Cost-effective solution that saves resources and labor costs in the long-term by reducing the need for manual temperature scans and providing an efficient process for identifying issues.

"Real-time monitoring of equipment is an essential tool for power companies seeking to enhance their maintenance processes and guarantee dependable, consistent service to their customers.”

IQ Management

IQ Management is a powerful solution that empowers utility companies to proactively manage their equipment performance.

Utilizes real-time monitoring to collect data from vital components, providing valuable insights into equipment health and functionality

Detects and alerts utility companies of potential issues in a timely manner, preventing equipment failures, downtime, and costly repairs

Continuously monitors equipment temps, weather conditions, ambient temps, loads, and identifies deviations from normal ranges

Offers customizable alerts and detailed historic data logs for advanced reporting and trend analysis

Helps power companies make data-driven decisions to optimize operations and improve efficiency.

Data Enrichment with SCADA integration

IQ Mobile

IQ Mobile is a powerful tool that helps field techs respond quickly to problems, preventing equipment failures and downtime

Helps field techs respond quickly to problems, preventing equipment failures and downtime, saving power companies money

Advanced real-time alarm notification system alerts field resources of potential issues and provides precise location of affected equipment for prompt response

Notifications can be sent to multiple individuals, or teams at once

Field techs can quickly acknowledge alerts and provide status updates to management

Key Benefits

Improved safety: By continuously monitoring the temperature of equipment, power companies can identify potential safety hazards before they occur and take proactive measures to prevent accidents.

Increased reliability: By detecting temperature anomalies in equipment, power companies can identify and fix potential problems before they lead to costly downtime.

Predictive maintenance: Sensor IQ can analyze temperature data over time to identify trends and predict when maintenance is needed, allowing power companies to schedule maintenance before equipment fails.

Reduced costs: By proactively identifying and addressing issues with equipment, power companies can reduce the costs associated with unplanned downtime and emergency repairs.

Remote monitoring: Sensor IQ can be accessed remotely, allowing power companies to monitor equipment from anywhere and respond to issues in real-time.